About Plastic Injection Molding

Injection molding is one of the most effective ways to create complicated parts while keeping costs low and quality high. An incredibly versatile process, injection molding works with a wide range of different designs, materials, and finishes. Often used as a custom service for plastic parts and assemblies, the manufacturing process is one of the most reliable methods for creating replicable parts without compromise on quality.

The Process

The injection molding process involves injecting plastic resin into metal molds to craft durable parts with complicated designs with impeccable precision, and it’s used to create everything from large parts for the aerospace industry to tiny parts for consumer electronics and countless things in between.

Injection molding’s low scrap rates, moderating operating costs, and duplicable nature cut unnecessary expenses while increasing consistency and reliability. Compared to CNC machining and 3D printing, plastic injection molding saves money while improving quality and precision.

Different parts require different machines to support the injection molding process, and our engineers help customers choose the right machine as well as the best construction methods for their projects. Based on plans created in CAD, SolidWorks, STEP, or similar programs, our mold makers and designers assess the following details:

- What the part is

- The part’s size

- Tolerances

- Intended materials such as PEEK or PVC

- Any other useful and pertinent information

What Are the Types of Injection Molding?

There are several different types of injection molding, and the right option varies based on the part’s design, the desired volume, and the project’s needs. Here are the main types of injection molding.

Low-volume injection molding

Low-volume injection molding refers to creating a low number of parts with the injection molding process. Manufacturers define low-volume differently. Many consider batches with fewer than 10,000 parts to be low-volume, while others classify projects with up to 100,000 parts as low-volume. Low-volume injection molding is ideal for companies that need on-demand manufacturing or a limited number of parts.

Two-shot molding

Also called dual-shot, double-shot, or multi-shot molding, two-shot molding features two or more thermoplastics molded together in a single cycle. The process involves molding one plastic part and moving that part to a second mold to add another type of plastic. Operators can then repeat the process as many times as needed. The use of multiple plastics improves the design and functionality of certain parts.

Overmolding

Like two-shot molding, over-molding uses two different materials. It involves creating one part, moving that to another mold, and then molding the second material over the first. Over-molding suits low-volume and on-demand projects, and the process often costs less than two-shot molding because it utilizes the same machinery as traditional molding options.

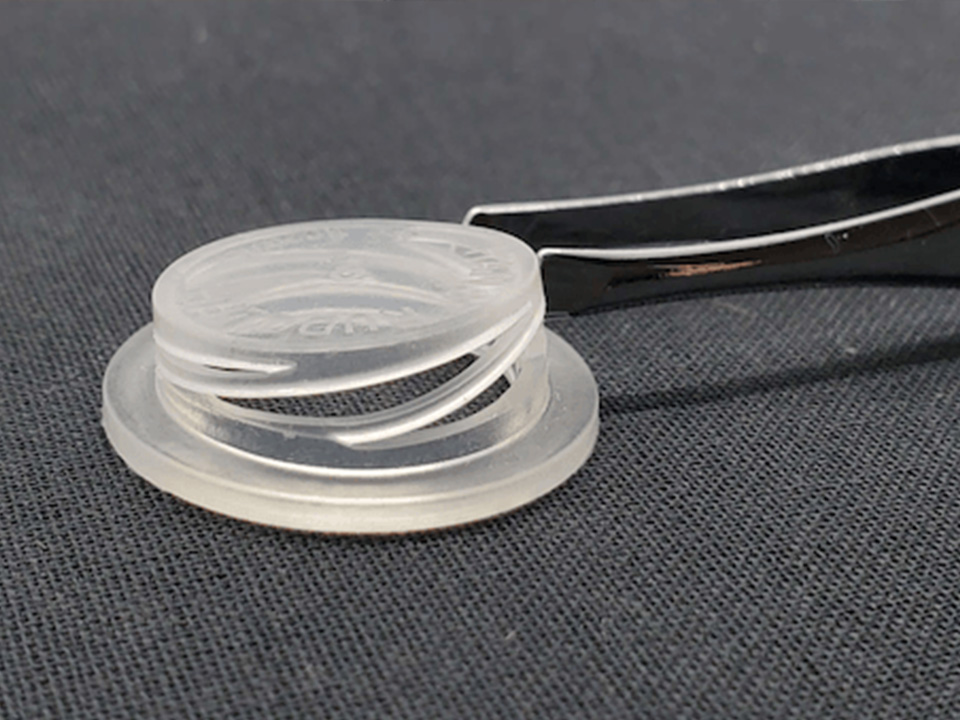

Silicone Molding (LSR)

Liquid Silicone injection molding produces parts that are highly water repellent and resistant. As such, coupled with the precise nature of their sizing, they’re ideal for use as seals, membranes, electrical connectors, and a variety of other medical, commercial and domestic applications.

How Does Plastic Injection Molding Work?

Plastic injection molding works by melting, molding, and cooling thermoplastic to create parts.

Operators melt and compress resin pellets so they can inject the resin into the mold’s runner system. After filling the runner system, they track factors like fill pressure and heat distribution. This safeguards against blemishes and imperfections and allows operators to identify and address issues immediately.

A shot of melted thermoplastic goes from the runner into the mold, and when it is firm and solid, the mold opens and ejector pins push the item out of the mold. Then, the mold closes, fills with another shot of thermoplastics, and the process continues to repeat until the batch is complete.

Thermoplastic Materials

Seaway’s customers can choose from several different types of thermoplastics including but not limited to:

- Acetyl

- Acrylic

- Liquid crystal polymers

- Nylon

- Polycarbonate

- Polyester

- Polyethylene

- Polyurethane

- And many others

Each material has a different price, pliability, density, impact resistance, susceptibility to sink, dimensional accuracy, and water absorption rates, and choosing the right material can be complicated. Customers need to consider the purpose of their part, but they also need to take into account its mechanical and physical properties as well as its need for resistance to chemicals, heat, electricity, flames, and UV rays.

Many parts can also benefit from resin additives such as glass and carbon fibers. Resin additives can strengthen composites, increase hardness, reduce creep, lower costs, make parts self-lubricating, control EMI or RFI interference, or meet other project goals. Again, different resins have different features, and customers need to ensure they’re making the optimal choice for their project. Seaway-Wright has worked with over 700+ different types of resin throughout the years. Ask what type you may need to fulfill your purpose.

Product Designs and Moldability

The right design is critical when using injection molding to produce parts. Customers need to embrace designs that lend themselves to accurate, high-quality molding, but they also need to ensure their designs meet the unique needs of their projects. To hone in on the right design, you should consider the following

- Wall thickness: Consistent wall thickness helps to cut the risk of warping or distortion.

- Core geometry: Coring out parts eliminates unnecessary thickness. Excessive thickness can alter dimensions, reduce strength, and increase the need for post-process machining.

- Material-specific designs: The design needs to complement the material you are using. For instance, ideal wall thickness varies based on molding material.

- Ramps: Ramps and slopes reduce the stress risks caused by sharp transitions.

- Radii: Using radii to smooth out sharp corners also helps to drop molded-in stress.

- Bosses: Designs should avoid thick sections around screw bosses or they may cause voids in the molded part.

- Ribs: Ribs should be less than 60% of the thickness of the walls.

- Core-cavity: When possible, core-cavity is superior to ribs. It provides constant wall thickness, a better surface finish, and a faster molding time.

- Fillets: This design feature strengthens the design by supporting itself.

- Draft: The sloping vertical walls of drafting allow the molding machine to eject the part without making marks or blemishes.

- Logos and tests: If you have to add logos or parts numbers, consider choosing a mill-friendly font, a limited depth between 0.010 and 0.015 inches, and increasing draft supports to create a smooth ejection that doesn’t mar your logo.

Project coordinators can help you learn more about other design considerations that complement the molding process. Contact us and consult with a Seaway engineer today!

Applications for Injection Molding

The aerospace, healthcare, automotive, electronics, consumer products, marine, and robotics industries as well as countless others rely on injection molding. This process provides businesses with the following benefits:

- Quick creation of prototypes

- Fast parts manufacturing

- Ability to test product functionality using CAD models during the development stage

- Low-volume production options for on-demand parts

- Mid and high-volume production options to create hundreds of thousands of parts in short time spans

- Manufacturing agility

Featured Case Study

Injection Molding

This healthcare company had been CNC machining parts for a specific device for COVID vaccines in 2020. However with their sudden increased need in volume, the company needed a more efficient alternative or lose time and money. This healthcare company had heard about SPE through their own network of subcontractors and decided to reach out. With this healthcare company production team seeking to solve this production problem, Seaway’s plastic injection molding services stood out to them as a more cost effective solution.

Offered at MME Group in St. Paul, MN

TWO SHOT MOLDING

Two shot molding features two or more different thermoplastics molded together in a single cycle. This kind of molding allows parts to improve their designs and functionality by combining two or more plastic parts. This helps to cut down on the need for post-molding assembly.

The difference between overmolding and two-shot molding is that in two-shot, the parts form a molecular bond rather than a mechanically or chemically induced bond. During this process, the machine injects one material into the mold, cools, and then is transferred to another cavity. Rotating 180⁰ the first meets the second substrate when the second is injected into that mold. This creates a firm bond between the two. Two shot molding is best for high volume operations. This is because of its efficiency and economy in producing highly durable and long-lasting assemblies and parts. For lower volumes, overmolding might be a better option.

OVERMOLDING

Like two-shot molding, over-molding uses two different and compatible materials. This multi-shot process combines these to create parts that won’t easily separate as time progresses. The first material used is usually of a more rigid quality to withstand the overmolding process. After the mold is injected with the first substrate and cools, it is then transferred to either an overmold tool or an overmold cavity within the same tool. Then the machine injects the second substrate over, into, or around the first. If necessary, the two substrates are then bonded either chemically or mechanically to provide a more stable product after cooling.

Over-molding usually suits low-volume or on-demand projects. Engineers often use overmolding because it is easier for design as they can fit in just about any standard injection molding machine for this process. Also, this process often costs less as it utilizes the same machinery of traditional molding options but with fewer transfers to different machines.

Offered at MME Group in St. Paul, MN

Liquid Silicone Rubber Molding

Liquid Silicone Rubber (LSR) molding is the process used to create robust, pliable, high-precision, high-quality parts in large numbers.

Liquid Silicone injection molding produces parts that are highly water repellent and resistant. As such, coupled with the precise nature of their sizing, they’re ideal for use as seals, membranes, electrical connectors, and a variety of other medical, commercial and domestic applications.

The process itself requires a large range of tooling knowledge and execution, unique equipment and mechanical components, all of which the MME Group has onsite. This capacity to provide LSR design, tooling, molding and full assembly services in one location makes MME the ideal LSR injection molding manufacturing partner.