Case Study

Industry: Defense

The specific defense contractor discussed in this case study has been an integral provider of premium products to defense companies nationally and internationally since its inception in 1969. With over 4000 employees and decades of industry experience, this defense contractor has worked diligently to develop a set of standards and requirements for their vendors to provide valid solutions. This includes maintaining ITAR registration, which provides governing and business principles for any company manufacturing parts or services for the defense industry. ITAR, known as the International Traffic in Arms Regulations, clearly outlines the policies and procedures manufacturers must adhere to in the interest of national security. In addition to supplying numerous national or international defense-related endeavors, this major defense contractor has provided innovative and high-quality solutions to law enforcement professionals and other related sectors that require comprehensive tools for professional use.

Our Objective

The objective clearly outlined through initial conversations with this major defense contractor was centered on improving the material, weight, and quality standards of an integral soldier-carried sighting system. This defense contractor specialized in constructing an advanced sighting system used by field-deployed military forces to complete high-level reconnaissance and information-gathering missions. When this company first approached Seaway for assistance in developing a new solution, the current sighting system possessed an undesirable weight largely related to the outdated resin from which it was made.

Through dedicated efforts and new technological advancements, the engineers at this major defense contractor were able to devise a revamped system that was 30% lighter than the first variant. This defense contractor also needed a few other aspects to meet their requirements. This included third-party validation of the parts, including government inspection, and that the parts meet the requirements in post-molding that would ensure quality maintained. Post-molding inspection also includes exhaustive testing, metrology verifications, and weight examinations to ensure all specifications for the customer are entirely met. Moreover, this defense contractor approached Seaway with a request for several thousand parts to construct the sighting system. While many plastic molding companies may consider this volume below their threshold, Seaway leaped at the opportunity to work closely with the defense contractor and manufacture a premium component.

The Results

Once the revamped sighting system designs were completed, this defense contractor came to Seaway in search of a plastic molding manufacturer that could meet the above-mentioned criteria, tighter in-process controls, and tolerances. Due to the discrete nature of completing jobs for various defense contractors, Seaway separates itself from competing providers as an ITAR-registered company that emphasizes a dedication to discretion and prioritizing national security efforts. By encouraging a collaborative work strategy, Seaway was able to quickly create the specific mold and establish a project process that would deliver quality components ahead of the originally estimated deadlines.

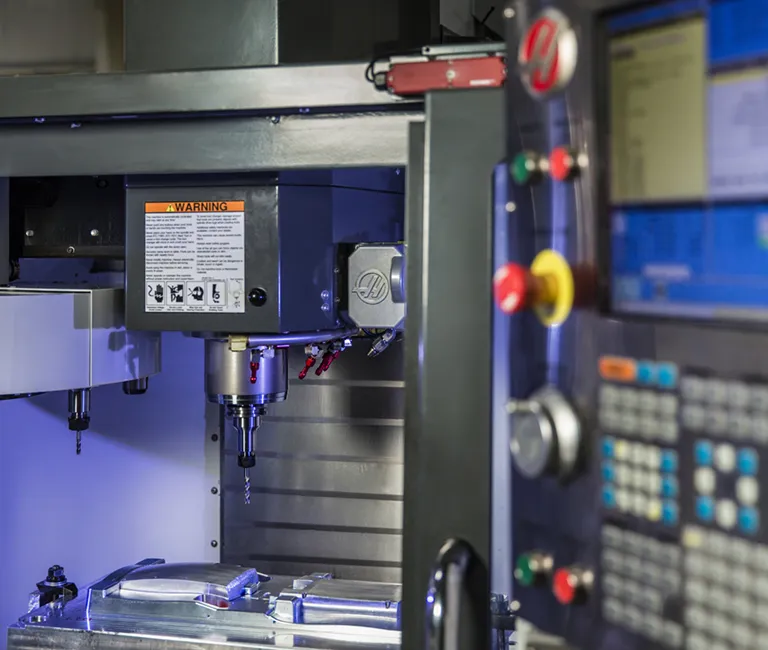

Seaway manifested the entire assembly using the highly engineered specialty resin the customer desired and helped save money on handling fees by streamlining the production process. This defense contractor and Seaway collaborated to keep the entire assembly’s production in one place to ensure the integrity of the overall device. This included additional post-molding services that would have originally been completed by other third-party vendors, further complicating the production process and increasing costs. For this specific project, Seaway completed the tooling, project molding, CNC machining, assembly, hardware installation, and painting completely in-house.

The quality assurances, machining expertise, and supplemental in-house services offered by Seaway delivered a high-quality product over twelve months of production with a negligible return rate of less than 0.001%.

Conclusion

In conclusion, the success of developing a sighting system with reduced weight and specialized engineered resin led to this specific defense contractor remaining with Seaway for years. This company has continued to utilize the collaborative work strategies and industry expertise of Seaway to continue manufacturing the parts they need to improve the performance and better protect members of the United States Armed Forces.

Through Seaway’s dedication to quality through ISO 9001 practices and ITAR-registered national security protocols, this major defense contractor obtained assemblies and parts that were lighter, more current with modern technology, and improved in-field performance. This successful case study is indicative of Seaway’s extreme proficiency and discretion in working with major defense contractors to develop detailed components through plastic molding. If you are searching for a similar product, please send us a message today with more information and we would be happy to discuss our offerings and provide a detailed quote.