Case Study

Industry: Medical

Our Objective

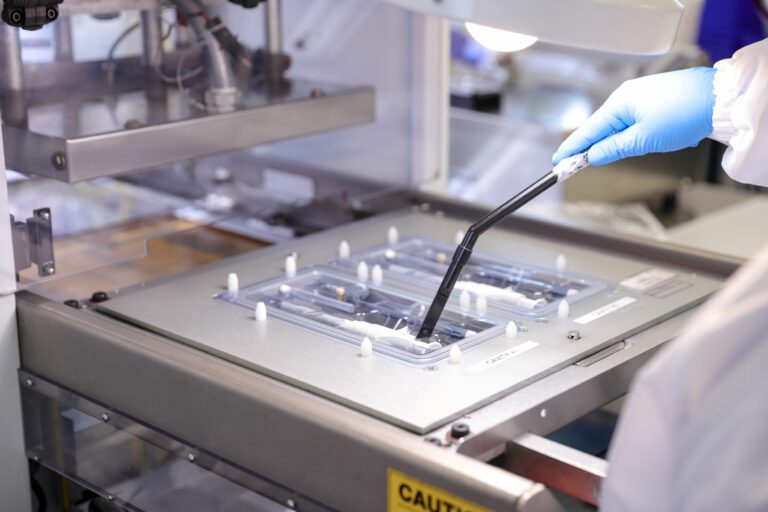

Wright Engineered Plastics partnered with an OEM to establish production procedures and facilitate the transition of their medical device into manufacturing. When financial constraints led to a Spinal Implant Company acquiring the project, Wright continued its collaboration, focusing on optimizing production and scaling operations.

The Results

Initially, Wright worked with the OEM to develop procedures and construct a new cleanroom, enabling successful market entry. Transitioning to the Spinal Implant Company, Wright streamlined production processes, collaborated with engineers, and developed fixtures to enhance efficiency. Scaling from low to mid-volume production, Wright’s expertise facilitated the transition, enabling the production from tens to hundreds to thousands of units.

Conclusion

Wright’s partnership with both companies resulted in a significant reduction in line fallout from 20% to 2%, demonstrating improved efficiency and quality control. Transitioning to plastic injection molding from machined parts expedited time-to-market, reduced stress points, and contributed to cost savings. Beyond production optimization, Wright’s involvement in troubleshooting and packaging refinement ensured correct device functionality and efficient packaging processes, establishing a lasting partnership built on trust and proven results.